The Health and Safety Executive (HSE) has launched a major consultation on proposed changes to the Control of Asbestos Regulations 2012, prompting warnings that UK businesses may soon face tighter compliance requirements and increased liability risks.

According to law firm Clarke Willmott, the consultation signals the potential for tougher expectations around asbestos management. The HSE is seeking feedback on three key proposals aimed at improving safety standards and strengthening protections for workers and building occupants.

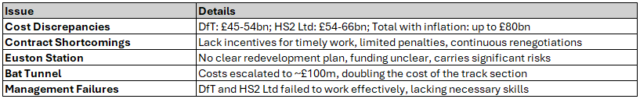

Three Proposed Changes to Asbestos Regulations

The consultation focuses on gathering views on reforms in three key areas:

- Improving independence in the four-stage clearance process

- Raising the standard and accuracy of asbestos surveys

- Providing clearer guidance on asbestos management duties

The changes are designed to reduce exposure risks and ensure more consistent compliance. With HSE estimating that around 5,000 people die each year from asbestos-related diseases, the regulator says improvements are essential for protecting both workers and the public.

Bridget Sanger of Clarke Willmott warned that while no legal changes have yet been implemented, the direction of travel is clear. She said: “While these proposals are not yet law, they indicate that compliance expectations may rise in the future. Businesses should take this consultation seriously and consider how the changes could affect their operations. It’s also a chance to think about practical challenges, influence guidance, and ensure that asbestos management processes are robust.”

Sanger urged firms to review internal procedures sooner rather than later: “Duty holders should review their asbestos management procedures, ensuring that surveys are up to date, clearance processes are independent and staff understand their responsibilities. It’s also important to clarify what counts as notifiable non-licensed work to avoid mistakes. Acting now can reduce the risk of fines, prosecution, or reputational damage, while ensuring a commitment to keeping people safe.”

Asbestos Still a Serious Risk in the UK

Despite asbestos being banned in the UK since 1999, it remains widespread in buildings constructed or refurbished before the ban.

New research published last month by High Speed Training highlights that the risks are far from historical. The training provider found that a significant number of employers and workers do not treat asbestos with the seriousness required.

According to the findings:

- 26% of tradespeople who encountered asbestos did not follow safe removal guidelines

- Another 26% said their employers instructed them to ignore those guidelines

- 35% did not believe asbestos is hazardous

- 36% viewed it as merely a “problem of the past”

Dr Richard Anderson, head of learning and development at High Speed Training, said the research underscores a major gap in awareness and compliance.

He said: “Whilst asbestos has been banned in the UK since 1999, it is still present in many buildings in the UK – with some reports stating it’s present in 1.5 million – and it can take as long as 30 years or more for symptoms of related diseases to appear, which really indicates the need for better awareness for tradespeople, their families, and the general public.

“Asbestos removal regulations are in place to make sure that the risk of exposure to harmful fibres is limited, and it’s imperative that guidelines are followed by a trained professional. It is never something that you should attempt to do yourself, whether you are a tradesperson or a member of the general public. There can be serious risks to your health if asbestos is disturbed and fibres are released into the air.”

The consultation provides an important opportunity for organisations to influence the future regulatory landscape while assessing their current level of compliance.

With the expected increase in enforcement and the ongoing risks highlighted by recent research, businesses that proactively strengthen their asbestos management procedures will be better positioned to meet rising standards and protect their workforce.