Whether with the Next Generation eCanter or the new Canter, Daimler Truck subsidiary FUSO will be demonstrating at bauma 2022 that it has convincing products for the construction industry in its portfolio in both the battery-electric and conventional commercial vehicle segments. Both vehicles offer intelligent solutions for a wide range of customer requirements in the light truck segment thanks to their robustness coupled with high payload, manoeuvrability and reliability. The FUSO brand stands for user-friendliness and agile driving comfort based on sustainable and efficient drive technologies. Both the Next Generation eCanter and its conventional brother Canter can get to work and transport bulk materials or machines such as the excavator needed on the construction site as well as skips or containers with a wide variety of bodies.

Customers, trade visitors and media representatives will be able to see what else sets both light trucks apart and makes them so attractive for the construction sector at this year’s bauma in Munich from 24-30 October, 2022. At the world’s leading trade fair for the construction industry, FUSO will be exhibiting both the battery-electric Next Generation eCanter and the new Canter.

The Next Generation eCanter exhibited at the FUSO booth B439 (Hall B4) is an 8.55-tonne truck equipped for the first time with a roll-off tipper from UNSINN as well as a mechanical power take-off and has a chassis load capacity of 5,135 kg. The payload is 3,635 kg. The vehicle with comfort single cab (three seats) has a wheelbase of 3,400 millimetres and is equipped with the M battery package, which enables a range of up to 140 kilometres.

The new FUSO Canter shown on the outdoor area is built as a 7.49-tonne truck with a three-way tipper from Meiller and a crane from Atlas and also has a comfort single cab. The vehicle has a wheelbase of 3,400 millimetres, a chassis load bearing capacity of 4.94 tonnes, a payload of 2.580 kg and an engine output of 129 kW.

Philipp Panter, Head of Sales, Marketing & Customer Service at FUSO Europe: “With our Next Generation eCanter, shown for the first time with a roll-off tipper, we are underlining that the advantages of the FUSO Canter for the construction industry are also fully reflected in the electrified variant. Thanks to their robustness and variability, the Next Generation eCanter and the new FUSO Canter are ideally suited for the construction industry. Together with our body partners, we can realise a wide variety of applications in both vehicles.”

Daniel Rauch, business unit manager for roll-off systems at UNSINN Fahrzeugtechnik: “As the exclusive partner of FUSO Europe, we are proud to have been able to play a part in the premiere of the Next Generation eCanter at bauma 2022 with our roll-off tipper system. It is the first vehicle in its weight class in Europe with a roll-off system superstructure. For us, the premiere represents an important milestone in the company’s history, because it is the first time we have supported a project in electric mobility. It represents a major technological development step towards the future.”

Next Generation eCanter: ready to go for even more sustainable and economical operation

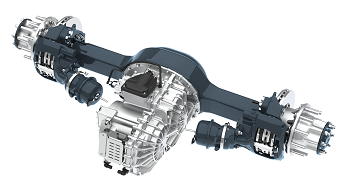

To better meet customer requirements, FUSO has made several changes to the Next Generation eCanter. While the electric truck was previously only available as a 7.49-tonner with a wheelbase of 3,400 millimetres, customers now have a choice of six wheelbases between 2,500 and 4,750 millimetres and a permissible gross weight of 4.25 to 8.55 tonnes. The body and payload capacity of the chassis is over 5.0 tonnes. The Next Generation eCanter is powered by either a 110 kW (variants with a gross weight of 4.25 and 6.0 tonnes) or 129 kW (variants with a gross weight of 7.49 and 8.55 tonnes) electric motor with an optimised driveline and 430 Nm of torque; the maximum speed is 89 km/h.

Depending on the wheelbase, three different battery packs are available: S, M and L. The batteries use lithium iron phosphate (LFP) cell technology. These are characterised above all by a long service life and more usable energy. The battery pack in the S variant has a nominal capacity of 41 kWh and enables a range of up to 70 kilometres. In the M variant, the nominal capacity is 83 kWh and the range is up to 140 kilometres. The L variant, the most powerful package, offers a nominal capacity of 124 kWh and a range of up to 200 kilometres. Recuperation can further increase the range, which at the same time minimises charging breaks. By comparison, the eCanter previously only had a battery option with a nominal capacity of 81kWh and a range of up to 100 kilometres.

As far as battery charging is concerned, the Next Generation eCanter is compatible with all mains voltages in the major markets. The charging unit supports charging with both alternating current (AC) and direct current (DC). The charging standard is the Combined Charging System CCS, and charging is possible at up to 104 kW. DC fast charging from 20 to 80% of capacity is possible in around 24 (S), 26 (M) and 39 minutes (L), depending on the battery pack. AC charging (11 and 22 kW) takes between around four and six hours, depending on the battery pack.

Competent consulting for tailored e-mobility

Because e-mobility is more than just a new powertrain, FUSO integrates the Next Generation eCanter into a holistic ecosystem that also includes tools and consulting services for high vehicle utilisation and optimisation of the total cost of ownership. Through a special analysis approach to total cost of ownership, FUSO dealers will offer each customer a completely individual calculation for operating the eCanter. It is also possible to use the Daimler Truck Incentive Tool to get an overview of incentives and benefits such as specific government subsidies for vehicles or charging infrastructure as well as tax reductions or toll waivers. Thanks to a strategic partnership with Siemens Smart Infrastructure and ENGIE, customers can also obtain comprehensive advice on the subject of DC charging infrastructure and receive a complete service package – from charging technology and installation to coordination with the network operator.

Versatile, comfortable and secure

Available in two cab variants (Standard at 1.7 metres wide and Comfort at 2.0 metres wide), the Next Generation eCanter is characterised not only by its overall ecological and economical concept but also by its versatility. The electric truck from FUSO is compatible with many superstructures typical of the construction sector, such as flatbeds or dump trucks, making it the ideal companion for a wide range of applications. What also makes the Next Generation eCanter particularly body-friendly and compatible is the optional equipment with a mechanical power take-off available ex works to supply hydraulic power units.

Numerous features and devices ensure a high level of comfort for the driver and road safety for all involved. The standard highlights include the multifunction steering wheel with buttons for controlling the fully digital LCD instrument cluster, LED headlights that are 30% brighter than halogen models for greater visibility, the Autolight function for controlling the headlights depending on the lighting conditions, and intelligent Highbeam Assist.

In terms of safety, the batteries are mounted under the vehicle’s chassis frame with a highly rigid steel bracket that also serves as impact protection for the battery in the event of a frontal or side crash. In the event of an accident, a crash sensor automatically deactivates the high-voltage system. For improved acoustic perception, for example by pedestrians or cyclists, the Next Generation eCanter is equipped with an external Acoustic Vehicle Alerting System (AVAS) as standard. For greater safety when turning right, Active Side Guard Assist is also fitted as standard. In addition, the next-generation Active Brake Assist emergency braking system with pedestrian detection, which is also standard, can reduce the risk of a collision in longitudinal traffic.

The new FUSO Canter: Ready for any requirement

Another highlight at this year’s bauma is the latest generation of the FUSO Canter, which has been in production since the beginning of 2022. For customers, this means another significant upgrade in terms of safety, comfort and cab design. Like its predecessor, the workhorse is available in five weight classes (3.5 to 8.55 tonnes), with six wheelbases (2,500 to 4,750 millimetres), three powerful engines (130 to 175 hp) and three cab variants (standard at 1.7 metres wide, comfort at 2.0 metres wide and double cab, also at 2.0 metres wide).

As a 4×4 variant, the Canter is a real all-rounder in the construction industry thanks to its selectable all-wheel drive and selectable reduction gearbox and self-locking differential.

What’s new is that FUSO now also offers the Canter as a 3.5-tonne truck with a standard-cab in all right-hand drive markets and has improved body-friendliness with a new wheelbase of 3,400 millimetres for these models.

Thanks to its variability with five gross weights and six different wheelbases, the Canter is suitable for almost any superstructure and can meet the requirements of almost any application and transport task – from the simple flatbed to the complex special vehicle. Combinations with a loading crane, a cherry picker or a concrete pump can also be realised without any problems. The robust steel ladder frame of the chassis is designed as a C-section, as on heavy trucks, and thus offers a particularly high load-bearing capacity. The chassis payload in the heaviest vehicle variant is around 6.0 tonnes – a real added value, especially for the construction industry. Factory-fitted power take-offs for hydraulic pumps or compressors and the optional 24-volt interface round off the Canter’s body-friendliness. With a newly developed compact exhaust system, the new FUSO Canter meets the EURO VI Step E emissions standard.

Advanced design and more safety

The redesigned front of the latest generation FUSO Canter combines traditional design elements with a modern design language, bringing together the form and functionality of a robust light truck. The upgrade of the cab exterior also reflects FUSO’s so-called ‘Black Belt’ design identity, which runs like a leitmotif through the designs of the Japanese brand’s other vehicles.

The new FUSO Canter also sets standards in the light truck segment in terms of safety for all road users. For example, the vehicle can now also be ordered with Sideguard Assist. Sideguard Assist uses a radar sensor to warn of moving objects and stationary obstacles on the passenger side of the truck. The system can assist and warn the driver as soon as it detects a risk of collision when the driver steers toward the passenger side or sets the turn signal on the passenger side. As in the previous model, other assistance systems such as the AEBS emergency braking system, Electronic Stability Program and LDWS lane departure warning system are also included. Safety is also enhanced by features such as LED headlights that are 30% brighter than halogen models for greater visibility, the new Autolight function for controlling the driving lights depending on the lighting conditions, and the reinforced rear underride guard, which is designed to minimise the impact of an accident.

Improved comfort

Over the past decades, FUSO has continuously improved its light truck to meet customer needs. Thanks to improved noise insulation, the new Canter impresses with an even lower interior noise level than the previous model. The spacious cab with good all-round visibility also enables the driver to manoeuvre easily. The Canter’s low entry height and comfortable step-through can help drivers navigate the roads even better. And at 10.2 metres, the FUSO Canter has the smallest turning circle in its class as a 3.5-tonne truck.