National Highways is warning road users that the M4 north of Bristol will be closed to allow steel beams for the new A432 Badminton Road Bridge to be lifted into place.

The M4 will be closed in both directions between junctions 18 (Bath) and 19 (M32) from 7pm Friday, 10th October to 6am Monday, 13th October.

The closure marks a key milestone for the scheme, which will see eight steel beams lifted into place across the motorway, marking the last full weekend closure of the M4 for this scheme and the final major stage of reconstruction.

Once the beams have been lifted into place, the remainder of the new bridge will be constructed with minimal disruption to the motorway below and will be open to the public in early 2026.

The new bridge – 46.5m in length and 20m wide – will span eight lanes of motorway but will be slightly wider.

This is to ensure the road lanes and pavements are wide enough to meet today’s safety standards. The barriers along the sides are higher to keep people walking and cycling safer.

Sean Walsh, Route Manager for National Highways, said: “The beam lift is a huge milestone in the construction of the new bridge, but we appreciate that any road closures can be frustrating for people.

“We need to fully close the M4 because we’ll be lifting eight 80-tonne steel beams into place, and it’s vital that we keep those doing the work and motorists safe.

“Once complete, the new bridge will help reconnect drivers, businesses and the local communities that have been impacted by the closure.”

With 3,000 to 4,000 vehicles using this section of the M4 every hour during peak weekend periods, the closure is likely to cause substantial disruption, and drivers are advised, where possible, to avoid the area and plan their journeys for alternative times.

National Highways thanks people for their patience while carrying out this significant construction work, which will bring smoother, more reliable, and safer journeys for road users.

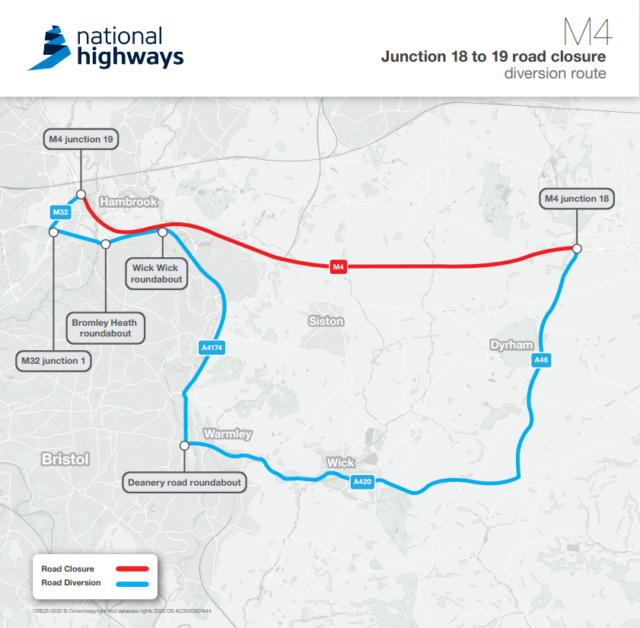

A diversion for westbound traffic will be as follows:

- From M4 junction 18, exit the motorway roundabout to the A46 heading towards Bath

- At the A46/A420 junction just past Pennsylvania, take the A420 towards Warmley

- At the A420/A4174 junction in Warmley, take the A4174 towards the M32

- Join the M32 at junction 1 and head to the M4 junction 19

- Follow directions above in reverse for exiting at M4 junction 19

The eastbound diversion will be in reverse.

Constructed in 1966, the Badminton Road bridge was a concrete post-tensioned structure. In July 2023, a planned detailed structural investigation revealed problems on the underside of the bridge, which meant it had to be closed to traffic.

Having considered the options, demolishing and replacing the existing structure was the quickest and most economical approach to restoring this important local link.

Work is progressing well on site, and the new bridge is due to be open to traffic in early 2026.